"15 Successful years with 50+ Major Global Projects."

We are the first to develop Innovative, Proven & State of Art Technology “ZPHB®” (Zero Pond®, Zero Pollution® & Higher Biogas®). This system is widely used for POME against the conventional systems. The conventional system consists of series of ponds which are uncovered open ponds. They have many environmental disadvantages and some countries have banned and in near future these ponds/lagoons are no longer allowed for POME Treatment. POME has very high strength effluent because of higher COD, BOD and Solids so it has to be treated properly through anaerobic process to capture biogas then followed by Secondary and Tertiary treatments to meet the local DOE regulations.

We are the first to develop Innovative, Proven & State of Art Technology “ZPHB®” (Zero Pond®, Zero Pollution® & Higher Biogas®). This system is widely used for POME against the conventional systems. The conventional system consists of series of ponds which are uncovered open ponds. They have many environmental disadvantages and some countries have banned and in near future these ponds/lagoons are no longer allowed for POME Treatment. POME has very high strength effluent because of higher COD, BOD and Solids so it has to be treated properly through anaerobic process to capture biogas then followed by Secondary and Tertiary treatments to meet the local DOE regulations.

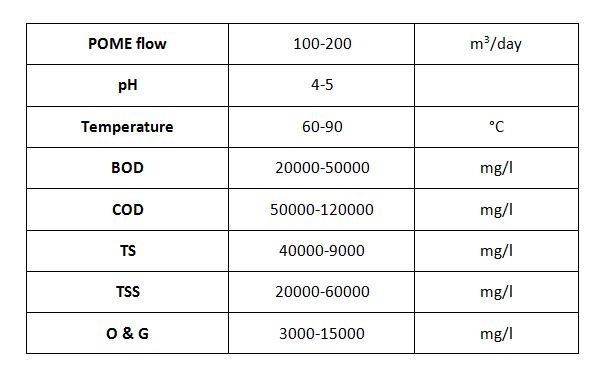

POME CHARACTERISTICS

POME flow and other parameters characteristic may vary based on Mill process conditions and project location.

ZPHB® TECHNOLOGY

There are many technologies available for treating the POME such as covered lagoons, CSTR and Membrane technologies for Mesophilic or Thermophilic conditions, but our ZPHB® technology has its own advantages and is a proven technology for POME treatment as all our projects are running successfully around the world on this technology. We introduced the concept of ZERO PONDTM system for POME treatment to capture higher Biogas and meet the local DOE discharge standards (BOD 100 or 20 mg/l).

ZERO POND® SYSTEM

We are providing zero pond system for new green mill projects/ revamping of the older system to capture biogas and meet the local discharge regulations. Our treatment system consists of below stages,

1. Pre Treatment

2. ZPHB® Reactor

3. Secondary Treatment

4. Tertiary Treatment

5. Gas Management

6. Sludge Management

ZPHB® FEATURES

1. Highly efficient anaerobic digestion and maximum removal of BOD, COD and Solids.

2. Higher Methane Biogas Capturing than other systems.

3. Process is simple and user friendly technology.

4. Hassle free operation and Maintenance.

5. Less foot print area, Power consumption and retention period.

6. Very Effective mixing technology is used for mixing so as to avoid any stratification inside and trouble free mixers and easy maintenance outside the tanks.

7. Low cost tank system with special grades (HR plates with E250) & anti-corrosive painting.

8. Special fool proof safety devices for Pressure and Vacuum.

9. Easy stabilization and smooth operation without any process disturbances.

10. Easy Operation and Monitoring through PLC/SCADA Systems.

ZPHB® – CONVENTIONAL SYSTEM FOR EXISTING PLANTS

We equip ZPHB® Technology for existing Palm Oil Mills effluent to capture biogas & to utilize in boiler as fuel or power generation through biogas engines. We are replacing the existing pond system / inefficient Covered lagoon / tank system with our ZPHB® technology for effective treatment of the effluent and capture more biogas. We can use the existing Cooling ponds/Collection ponds for temperature reduction and then pumped to our ZPHB® reactor for degradation, then treated POME enters into the existing open ponds for further removal or it can be further utilized for land application based on site conditions and DOE approval.