"15 Successful years with 50+ Major Global Projects."

We provide complete turnkey for domestic, industrial and municipal sectors ranging from small, medium and large scale sewage treatment plant.

We ensure that sewage is treated properly to get reduced pollutant load before discharge into water streams or reuse application based on local ENVIRONMENTAL/ GOVT/DOE /PCB regulations and industrial needs.

PRE & PRIMARY TREATMENT

Pre-treatment consists of Collection sump, Manual screen, Mechanical screen, Fine screen then Grit chamber. These processes ensure removal of all floating materials and silt/ inert materials before it is fed into further process for smooth operation of the plant. Primary Treatment is the Sedimentation tank / Primary Clarifier for the removal of suspended solids and part of organic materials before feeding into secondary treatment so that it helps to reduce the load to secondary treatment and removing solids which will be further treated in anaerobic process to produce bio energy.

UASB TREATMENT

After Pretreatment, the sewage will be fed to UASB reactor. The generated biogas will be used for power generations. The treated sewage/overflow will be taken to secondary treatment for further removal of pollutants and organic material.

SECONDARY TREATMENT

We provide wide range of Process from Conventional Activated Sludge Process with advance technology for removal of nutrients from the secondary treatment depending on the inlet characteristics and local DOE regulations.

1. Conventional Activated sludge process – Surface Aerators/Diffuser Type Aeration

2. Moving Bed Biological Reactor (MBBR)

3. Integrated Fixed Film Activated sludge (IFAS) for nitrogen removal

4. Sequential batch Reactor (SBR)

5. Membrane Bio Reactor (MBR)

TERTIARY TREATMENT

Tertiary Treatment includes disinfection and filtration process after which the treated water is used for irrigation or any other municipal/industrial reuse. This can be achieved by Settling/high rate clarifier/sedimentation tank, filtration or membrane filtration then disinfection so that it meets the most stringent standards of re-use application.

SOLIDS TREATMENT & POWER GENERATION

Solids from primary treatment and biological treatment will be collected in thickener process to increase the solids consistency. This is then fed into anaerobic reactor for further degradation of organic materials to produce Biogas. Bio-solids will be dewatered through Centrifuge / Decanter to further minimise the load before disposal to land. The generated biogas will be collected in Gas Holder then passed through Scrubber system for removal of Hydrogen Sulphide (H2S) before it is fed into Biogas Gas engine to produce Electricity. The produced electricity will be used for in-house consumption & excess will be sent to local electricity grid.

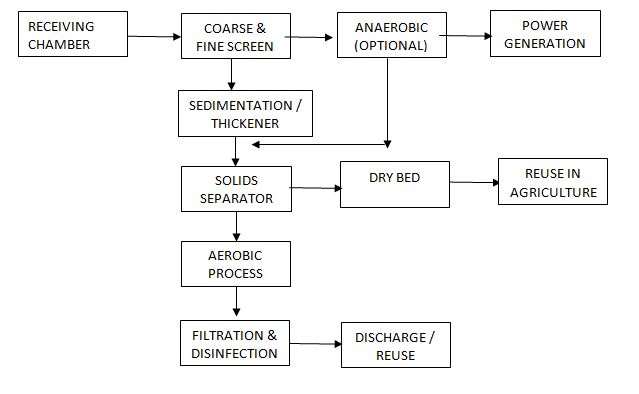

FAECAL SLUDGE AND SEPTAGE TREATMENT PLANT

We are providing complete turnkey solutions for Faecal and Septage sludge treatment to meet the discharge standard for disposal and reuse applications. Faecal and Septage sludge having high concentration of organic compounds, suspended solids, high oxygen demand, high content of pathogen, unpleasant and unstable in nature. FSTP design scheme is based on the nature of sludge either Conditioned or Unconditioned characteristics. Below is treatment scheme which will meet the local DOE/ PCB regulations. The unconditioned/ fresh faecal sludge can be treated in Anaerobic process with our ZPHB® Reactor to produce green energy which can be used for inhouse power consumption. The final treated water and solids can be used for agricultural usages.